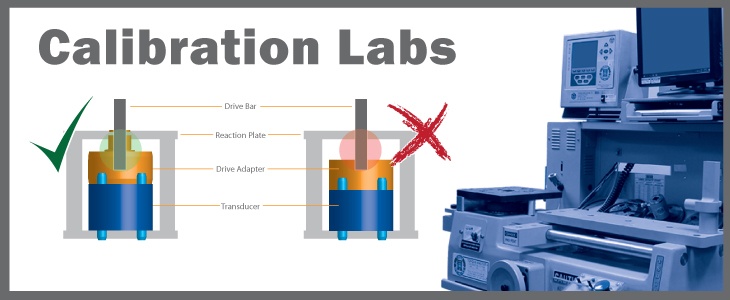

With some of our wrenches having ±0.4% accuracy and our standard wrenches at ±1%, we at Advanced Torque Products have needed to research and test the best practices for calibration in order to achieve and maintain this standard. Through managing and maintaining our own calibration lab and visiting many others over the years, we’ve seen the good, the bad, and the ugly and learned from it all.

Eric Cohen

Recent Posts

Formulating an efficient and accurate Calibration Lab

Posted by Eric Cohen on Nov 8, 2018 8:17:00 AM

0 Comments Click here to read/write comments

Topics: Torque Wrench Calibration, Tool Accuracy, Wrench Accuracy

Torquing the Airbus EC145 Mast Nut Just got easier

Advanced Torque Products (ATP) has been working hard with Airbus to improve the torquing method of the mast nut on the EC145. And they’re excited to announce this custom tooling kit is now available to anyone working on the EC145 mast nut.

This tooling was developed working directly with maintenance professionals in the Airbus training facility to assure it met all the needs of the tool operators. The ATP760 drastically reduces application time, increases accuracy to within +/-1%, takes away operator fatigue from holding the tool in place and increases overall operator safety.

For more information, visit www.advancedtorque.com.

Read More

Advanced Torque Products (ATP) has been working hard with Airbus to improve the torquing method of the mast nut on the EC145. And they’re excited to announce this custom tooling kit is now available to anyone working on the EC145 mast nut.

This tooling was developed working directly with maintenance professionals in the Airbus training facility to assure it met all the needs of the tool operators. The ATP760 drastically reduces application time, increases accuracy to within +/-1%, takes away operator fatigue from holding the tool in place and increases overall operator safety.

For more information, visit www.advancedtorque.com.

0 Comments Click here to read/write comments