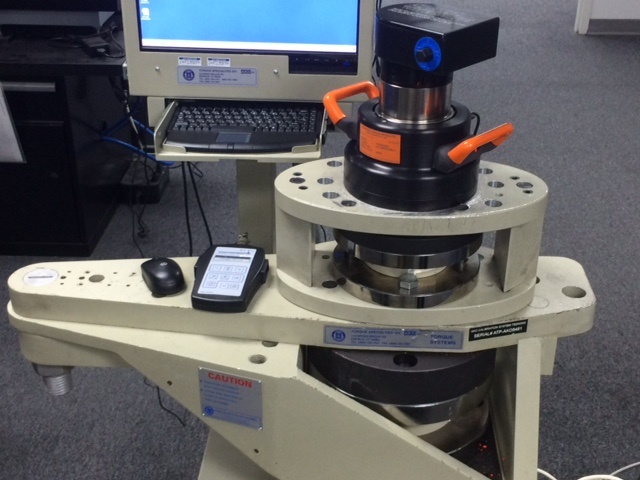

With some of our wrenches having ±0.4% accuracy and our standard wrenches at ±1%, we at Advanced Torque Products have needed to research and test the best practices for calibration in order to achieve and maintain this standard. Through managing and maintaining our own calibration lab and visiting many others over the years, we’ve seen the good, the bad, and the ugly and learned from it all.

Formulating an efficient and accurate Calibration Lab

Posted by Eric Cohen on Nov 8, 2018 8:17:00 AM

Topics: Torque Wrench Calibration, Tool Accuracy, Wrench Accuracy

Quality equipment only stays quality equipment if it receives the level of care it deserves.1

I came across this quote when researching best practices for maintaining and caring for corporate equipment. What struck me about the quote is how it applies not only to big-ticket equipment in a corporate environment, but also to the things we use on a daily basis in our personal lives. I make sure my car’s oil is changed on a regular schedule, the belts are checked for wear, and filters are replaced in the hopes of extending the life of the vehicle. I protect my iPhone with a case to prevent it from damage if dropped. Regular preventive maintenance for corporate equipment is even more important, as the cost of unplanned downtime, delayed product delivery, and customer service issues can severely hurt even the most successful company. Equipment failure can also have a ripple effect if the failure of a tool or machine consequently damages other tools and equipment.

Topics: Torque Wrench Calibration, Tool Accuracy, torque wrench care

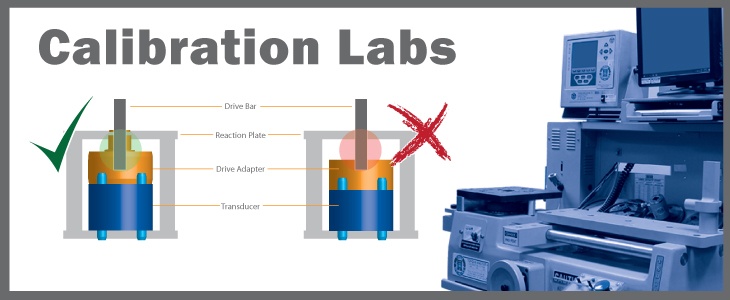

To ensure accuracy, measuring devices are calibrated on a regular basis. Calibration is defined as the setting or correcting of a device by adjusting it to match a dependably known and unvarying measure. It compares the reading from the device that is being calibrated to a standardized measure, and the results are presented on a calibration certificate. A torque wrench, which is used to precisely apply a specific torque to a fastener such as a nut or bolt, is an example of a tool that requires regular calibration. When used in aerospace applications, an inaccurate wrench may over-torque or under-torque a bolt which could lead to aircraft failure and the increased likelihood of an accident resulting in injuries or even fatalities. Regular calibration reduces the possibility of inaccurate measurements and reduces the period of time in which an inaccurate tool could be used.

Topics: Torque Wrench Calibration